views

When choosing an electronic contract manufacturer or ECM for your company, do you know what to search for? With everyone in the market providing identical services, identifying the best among them is a challenge. But the best companies like top-class electronic contract manufacturers near me always perform on certain aspects that have a direct impact on cost savings, product quality, and peace of mind.

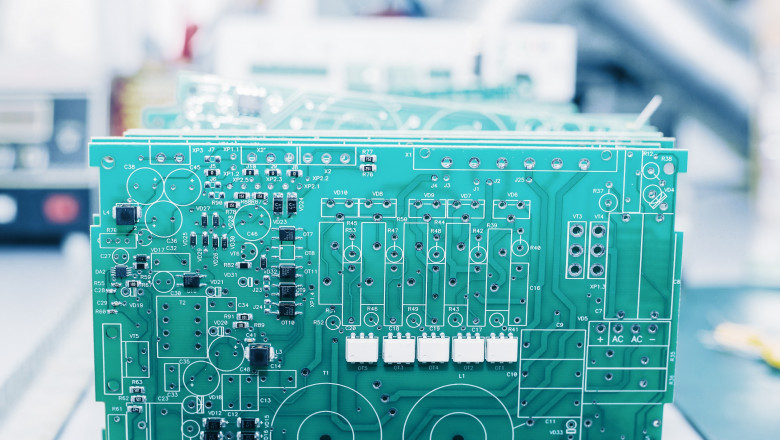

1. State-of-the-Art Manufacturing Facilities

State-of-the-art manufacturing centers are one sign of a stable ECM. The industry leaders put money into newer technologies such as surface-mount technology (SMT) lines, advanced robotics, and high-precision inspection machines.

These factories provide high production rates and reliability with minimum potential for human error. To illustrate, an ECM factory equipped with automated optical inspection systems has higher accuracy at soldering defects detection compared to manual methods, eliminating you from costly rework later.

Ask how they have set up manufacturing when considering purchasing an ECM. Are they sticking with old processes or leveraging recent developments to give you maximum efficiency?

2. Stringent Quality Control

Quality is not an option when producing electronics. Bad quality can not only cause customer dissatisfaction but also possible safety risks, particularly in industries such as healthcare and automobile.

Top-of-the-line ECMs have extensive quality control checkpoints throughout the manufacturing process. They follow globally accepted standards such as ISO 9001, IPC-A-610, and compliance to RoHS. These standards provide assurance that each product passes rigorous quality standards prior to shipment from the factory.

Manufacturers should also provide failure analysis and corrective action procedures in the event of defects. Working with a manufacturer that is proactive in ensuring quality can save you time, money, and your reputation.

3. Scalability for Your Business Needs

Scalability needs to be a consideration when selecting an ECM - your manufacturing partner needs to be able to scale with you as your business grows.

For example, suppose your company introduces a hot-selling IoT product. A scalable ECM will be able to handle a rush of orders without slowing down or sacrificing quality.

Top-tier contract manufacturers usually have flexible batch sizes—either a small prototype run or an enormous production order. This flexibility is especially important for startups that are planning to scale quickly.

4. Customized Design and Engineering Support

Not every ECM goes only as far as manufacturing. The top contract manufacturers make product development contributions in the form of design and engineering capabilities. They can use their expertise to streamline your product design to eliminate waste, cut costs, or improve performance.

For instance, take Design for Manufacturability (DFM) and Design for Testing (DFT) analysis. These activities guarantee that your product design is optimized for cost-effective manufacturing and simple testing, minimizing production bottlenecks and possible failures.

Selecting a partner with an experienced engineering team not only simplifies production but can also result in creative solutions for intricate projects.

5. Supply Chain and Component Management Expertise

One frequently overlooked feature when analyzing ECMs is how effectively they can manage the supply chain. The world's electronics sector is subject to challenges such as shortages in materials, volatile component costs, and trade impediments. World-class manufacturers have in place methods to counteract these problems.

For example, they have established relationships with trusted vendors to provide top-quality parts even in the event of worldwide shortages. Several use sophisticated computer software systems to monitor inventory and forecast demand to continue production unbroken.

A shining practice is providing counterfeit component detection programs. This guarantees that electronic components within your products are genuine, of high quality, and obtained ethically.

6. Transparent Communication and Strong Partnerships

The last characteristic of a first-rate ECM is a dedication to communicating in plain language and cultivating robust client relationships. Manufacturing is an intensely cooperative endeavor, and regular reporting is essential to reducing mistakes and fostering trust.

Great ECMs provide detailed production timelines and proactively share updates—whether it’s delivery schedules, changes in costs, or unexpected challenges. They also offer dedicated account managers to ensure a seamless experience and serve as a single point of contact for your inquiries.

These kinds of open practices build confidence and make sure you're in the know during the entire production cycle. In addition, long-term relationships with a reliable ECM provide strategic benefits, such as discounted prices for bulk purchases and preferential treatment during busy periods.

Conclusion

Partnering with a best-in-class electronic contract manufacturer might be a make-or-break business move. By making sure that they have these six qualities - state-of-the-art facilities, quality control, scalability, engineering support, solid supply chain abilities, and good communication - you put your business ahead of the pack.

Are you ready to elevate your product manufacturing process? Research thoroughly about top-tier electronic contract manufacturers near me, ask the right questions, and partner with a manufacturer who aligns with your long-term goals. With the right ECM, innovation and efficiency become your new norm.

Comments

0 comment