views

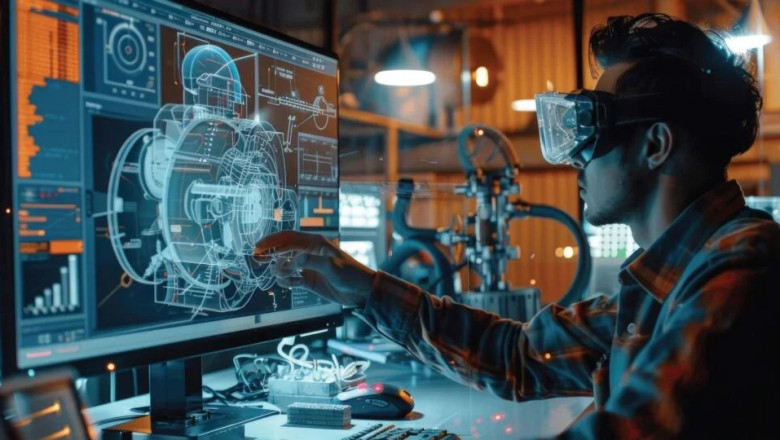

The industrial sector is undergoing a radical transformation, with the rise of digital technologies reshaping traditional manufacturing processes. One of the most promising innovations to emerge in recent years is the Industrial Metaverse, a concept that combines virtual reality (VR), augmented reality (AR), and the Internet of Things (IoT) to create immersive and interconnected digital ecosystems. This new era is poised to redefine how manufacturing operations are designed, executed, and optimized, offering unprecedented levels of efficiency, innovation, and collaboration.

Introduction to the Industrial Metaverse

The Industrial Metaverse refers to a virtual space that integrates the physical world of manufacturing with digital models, simulations, and data. It enables organizations to create a connected environment where products, processes, and people interact in real-time within an immersive, virtual space. By bridging the gap between physical and digital realms, this metaverse allows manufacturers to visualize, simulate, and optimize their operations with greater precision and effectiveness.

In this virtual space, factories, supply chains, and even entire production lines can be replicated digitally, allowing companies to experiment and innovate in a risk-free environment. From design to maintenance, the Industrial Metaverse opens up new possibilities for manufacturers, helping them to adapt to market changes faster, improve productivity, and reduce costs.

Key Technologies Behind the Industrial Metaverse

Several key technologies enable the creation and functionality of the Industrial Metaverse, each playing a crucial role in its development:

- Virtual Reality (VR): Provides immersive experiences by allowing users to interact with and manipulate 3D digital environments, making it ideal for training, design, and virtual prototyping.

- Augmented Reality (AR): Enhances real-world experiences with digital overlays, offering real-time guidance and information to workers on the factory floor, improving operational efficiency.

- Internet of Things (IoT): Connects machines, devices, and sensors to collect and share data, creating a more intelligent and automated manufacturing environment.

- Artificial Intelligence (AI): Enhances decision-making, predictive maintenance, and process optimization, enabling smarter production workflows.

- Digital Twins: Virtual replicas of physical assets that provide real-time monitoring and data analytics, allowing for the simulation and optimization of production processes.

Together, these technologies provide a comprehensive framework for manufacturers to embrace the Industrial Metaverse and revolutionize their operations.

Applications in Manufacturing

The Industrial Metaverse has several key applications in the manufacturing sector:

- Product Design and Prototyping: Manufacturers can create virtual models of products, test them in various scenarios, and make adjustments before physical production begins, reducing the need for costly prototypes.

- Virtual Training and Simulation: Using VR and AR, companies can provide immersive training experiences for workers, enhancing safety and reducing training costs. Workers can practice complex tasks in a simulated environment, gaining hands-on experience without the risk of errors.

- Remote Maintenance and Support: Technicians can use AR to troubleshoot and repair machinery remotely, accessing real-time data and guidance without the need for on-site visits. This reduces downtime and enhances productivity.

- Supply Chain Optimization: With real-time data and digital twins, companies can gain greater visibility into their supply chains, track performance, and predict potential disruptions, enabling more agile and efficient operations.

Benefits of the Industrial Metaverse

The Industrial Metaverse offers numerous benefits for manufacturers:

- Increased Efficiency: By simulating processes, manufacturers can identify bottlenecks and optimize workflows, improving overall operational efficiency.

- Cost Savings: Virtual prototyping and testing reduce the need for physical prototypes, leading to significant cost savings in the design and production stages.

- Enhanced Collaboration: Virtual environments enable teams from different locations to collaborate in real-time, breaking down geographical barriers and improving teamwork.

- Improved Safety: Immersive training and real-time support reduce workplace accidents, ensuring that employees are better prepared for complex tasks.

Challenges and Considerations

While the potential of the Industrial Metaverse is vast, there are several challenges to consider:

- High Initial Investment: Setting up the necessary infrastructure, such as VR/AR equipment, IoT devices, and AI-powered systems, can require significant investment.

- Data Security and Privacy: With the integration of multiple digital systems, ensuring the security and privacy of sensitive manufacturing data is crucial to prevent cyber threats.

- Technological Integration: Integrating existing legacy systems with new technologies can be a complex and time-consuming process.

- Skilled Workforce: As the Industrial Metaverse evolves, there is a need for a workforce skilled in emerging technologies such as AI, VR, and IoT.

Future of Immersive Manufacturing

The future of the Industrial Metaverse looks promising, with advancements in AI, 5G connectivity, and blockchain paving the way for more sophisticated and secure manufacturing environments. As technology continues to evolve, the Industrial Metaverse will become more accessible, enabling smaller manufacturers to leverage its benefits. The integration of more intelligent automation systems, coupled with real-time data and digital simulations, will further enhance the efficiency and flexibility of manufacturing operations, creating a new era of immersive and connected manufacturing.

For More Info: https://bi-journal.com/industrial-metaverse-immersive-manufacturing/

Conclusion

The Industrial Metaverse is transforming manufacturing by merging physical and digital worlds, enabling companies to optimize their operations, reduce costs, and enhance collaboration. While there are challenges to overcome, such as high investment costs and the need for skilled workers, the long-term benefits far outweigh the obstacles. As technologies continue to develop, the Industrial Metaverse will unlock new possibilities, creating a more efficient, agile, and innovative manufacturing landscape.

Comments

0 comment