views

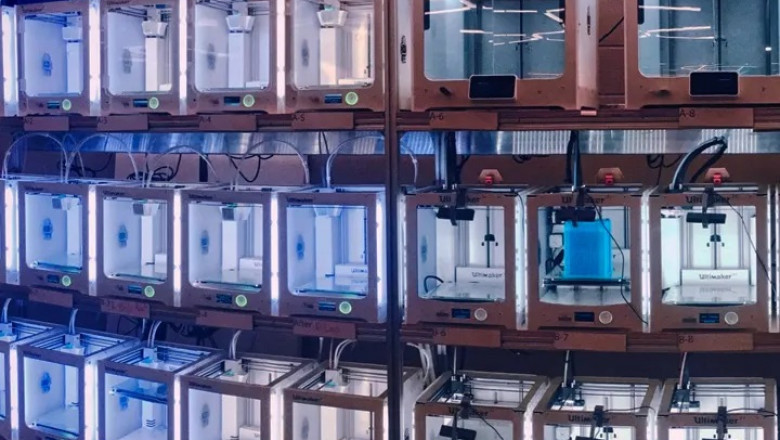

Organizations increasingly deploy multiple 3D printers to meet production demands in today's manufacturing landscape. At 3DPrinterOS, we've observed that efficient management of these printer arrays is not just beneficial—it's essential for operational success. As 3D printing transitions from prototyping to full-scale production, implementing robust 3D printer farm management software becomes critical for maintaining workflow efficiency and quality control.

Benefits of Implementing 3D Printer Farm Management Software

Organizations leveraging 3D print farm software gain significant advantages over traditional management approaches:

Centralized Control

Monitor and control dozens or hundreds of printers from a single dashboard, eliminating the need to physically interact with each machine individually. This centralization dramatically reduces administrative overhead and enables efficient resource allocation.

Enhanced Productivity

Automated queue management, job distribution, and load balancing ensure continuous operation across all printers. After implementing comprehensive farm management solutions, our clients report up to 70% productivity increases.

Real-time Monitoring

Track print progress, material usage, and printer status simultaneously across the farm. This visibility allows immediate intervention when issues arise, reducing failed prints and material waste.

Data-driven Decision Making

Collect comprehensive metrics on printer performance, utilization rates, and job histories. These analytics provide actionable insights for capacity planning, maintenance scheduling, and workflow optimization.

Streamlined User Management

Implement role-based access controls and approval workflows to manage which team members can access specific printers or initiate particular jobs.

Key Features to Look for in Management Software

When evaluating 3D printing farm software solutions, consider these essential capabilities:

- Intelligent Queue Management: Automated job distribution based on printer capabilities, material requirements, and production priorities

- Fleet Monitoring: Real-time status updates across all connected printers with alert systems for errors or completion notifications

- Remote Control: Ability to start, pause, or cancel print jobs from anywhere

- Resource Tracking: Comprehensive material inventory management and consumption tracking

- API Integration: Connectivity with existing production systems, MES, and ERP platforms

- Scalability: Architecture that accommodates growth from a few printers to hundreds without performance degradation

3DPrinterOS incorporates these features within an intuitive interface designed specifically for manufacturing environments ranging from small operations to enterprise-level printer farms.

Challenges in Managing a 3D Printer Farm

Even with powerful management software, printer farms present unique challenges:

Network Infrastructure

Maintaining reliable connectivity across dozens or hundreds of printers requires robust network planning. Consider dedicated networks for printer communication to prevent bandwidth issues affecting production.

Standardization vs. Specialization

Balancing the efficiency of standardized equipment against the need for specialized printing capabilities requires thoughtful planning and appropriate software configuration.

Maintenance Scheduling

Coordinating preventive maintenance while minimizing production disruption becomes increasingly complex as farm size grows. Management software should facilitate maintenance planning based on actual usage patterns.

Material Logistics

Sophisticated inventory tracking is required to ensure a consistent material supply across multiple machines. Look for solutions that provide alerts when supplies run low and track consumption patterns.

Best Practices for Effective 3D Printer Farm Management

Implementing these strategies alongside 3D printer farm management software maximizes operational efficiency:

- Establish Clear Workflows: Define standard procedures for job submission, approval, and post-processing

- Implement Printer Specialization: Designate specific printers for particular materials or applications based on demand patterns

- Create Redundancy Plans: Develop protocols for redistributing critical jobs when specific printers require maintenance

- Standardize File Preparation: Establish consistent slicing parameters and file preparation guidelines to ensure predictable outcomes

- Develop Training Programs: Ensure all operators understand both software interfaces and physical printer operation

3DPrinterOS facilitates these best practices through customizable workflow tools and comprehensive documentation resources.

Conclusion

As 3D printing transitions into production environments, the management infrastructure supporting these operations becomes increasingly crucial. Adopting specialized 3D print farm software is essential for scaling operations efficiently while maintaining productivity and quality standards.

By implementing a comprehensive management solution like 3DPrinterOS, organizations can transform disconnected printer arrays into cohesive production systems with centralized control, optimized workflows, and data-driven decision-making. This foundation not only improves current operations but establishes the scalability needed for future growth—turning the complexity of multiple printer management into a strategic manufacturing advantage.

Comments

0 comment