views

Metal Powder Market Leaders in Growth: Share, Value, Size, and Scope Analysis

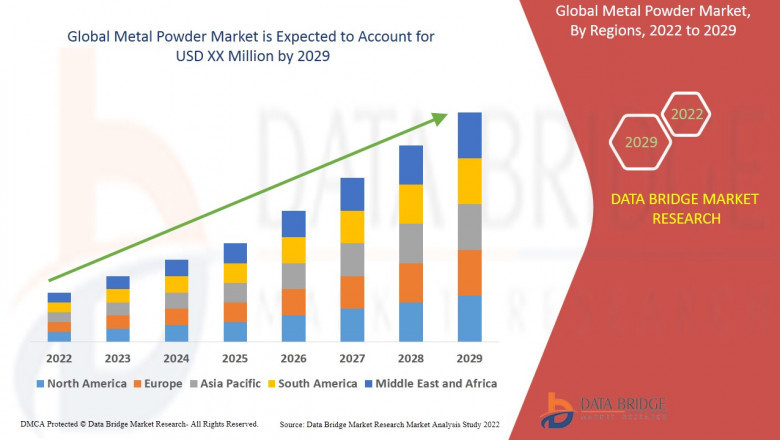

Metal Powder Market Size And Forecast by 2029

According to Data Bridge Market Research The metal powder market is expected to witness market growth at a rate of 5.35% in the forecast period of 2022 to 2029.

Metal Powder Market is making significant strides in the industry with its latest advancements and strategic expansions. As a leading player, Metal Powder Market continues to revolutionize the sector with cutting-edge solutions and a commitment to excellence. The company’s recent initiatives have strengthened Powder Metallurgy Market position in the global market, driving growth and innovation. With a strong focus on customer satisfaction, Fine Metal Particles Market has introduced new products and services designed to meet the evolving demands of consumers. By leveraging advanced technologies, Additive Manufacturing Metal Powder Market is set to redefine industry standards and enhance its competitive edge.

Metal Powder Market remains dedicated to sustainability and market leadership through innovative approaches. The company has expanded its operations, ensuring Sintered Metal Market footprint grows across multiple regions. With increasing demand, Metal Powder Market is investing in research and development to drive continuous improvement. The latest reports highlight Metal Powder Market impressive performance, reinforcing its role as a market leader. Moving forward, Metal-Based 3D Printing Powder Market aims to strengthen its impact through sustainable and customer-centric solutions.

Our comprehensive Metal Powder Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-metal-powder-market

**Segments**

- **Type**: The global metal powder market can be segmented based on type into ferrous and non-ferrous metal powders. Ferrous metal powders include iron, steel, and other alloys, while non-ferrous metal powders consist of aluminum, copper, nickel, and others.

- **Production Method**: Metal powders can also be categorized based on the production method used, such as mechanical methods (crushing, grinding) and physical methods (atomization, electrolysis).

- **Application**: The market can further be segmented by application, including additive manufacturing, powder metallurgy, welding, thermal spraying, and others.

- **End-Use Industry**: End-use industries of metal powders include automotive, aerospace, healthcare, electronics, and more.

**Market Players**

- **Rio Tinto Metal Powders**

- **Sandvik AB**

- **GKN plc**

- **Höganäs AB**

- **Carpenter Technology Corporation**

- **ATI Powder Metals**

- **Praxair Surface Technologies**

- **Australian Metal Powders Supplies**

- **Laiwu Iron & Steel Group**

- **AMETEK Specialty Metal Products**

The global metal powder market is experiencing significant growth due to the increasing demand from various industries such as automotive, aerospace, and healthcare. The ability of metal powders to enhance the performance and durability of products through processes like powder metallurgy and additive manufacturing is driving their adoption across different sectors. The ferrous segment holds a substantial market share as iron and steel powders are widely utilized in manufacturing processes. On the other hand, the non-ferrous segment, consisting of metals like aluminum and copper, is also witnessing growth owing to their lightweight and corrosion-resistant properties.

In terms of production methods, the physical methods segment, particularly atomization, is gaining traction due to its ability to produce fine and spherical metal powders that are suitable for various applications. Mechanical methods such as crushing and grinding are also utilized, especially for recycling purpose. The application of metal powders in additive manufacturing is growing rapidly as it enables the production of complex geometries and customized components. Similarly, in the aerospace industry, metal powders are extensively used for manufacturing lightweight components with high strength and performance.

The automotive industry is a key driver of the metal powder market, with the demand for metal powders in the production of engine parts, gears, and other components. The healthcare sector also presents significant opportunities for metal powder manufacturers, especially in the production of medical implants and devices. The electronic industry's requirement for high-conductivity metal powders for electrical components further contributes to market growth.

In conclusion, the global metal powder market is poised for continued expansion, driven by technological advancements, the adoption of metal powders in various industries, and the development of innovative products and applications. Market players need to focus on research and development to meet the evolving needs of end-use industries and establish strong partnerships to ensure a competitive edge in the market.

The global metal powder market is poised for sustained growth, driven by a combination of factors such as increasing industrial demand, technological advancements, and the versatility of metal powders in diverse applications. One of the key trends shaping the market is the rising adoption of metal powders in additive manufacturing processes. Additive manufacturing, also known as 3D printing, offers the ability to create complex geometries and customized components with high precision and efficiency. This trend is particularly prominent in industries like aerospace, automotive, and healthcare, where the demand for lightweight yet durable components is driving the need for advanced manufacturing techniques.

Another significant driver of the metal powder market is the growing emphasis on sustainability and resource efficiency in manufacturing processes. Metal powders enable manufacturers to reduce material wastage, energy consumption, and production costs compared to traditional manufacturing methods. This eco-friendly aspect of metal powders is resonating well with industries looking to enhance their sustainability practices while maintaining quality and performance standards.

Furthermore, advancements in production methods, such as atomization and electrolysis, are enhancing the quality and characteristics of metal powders, making them more suitable for demanding applications across various industries. For instance, atomization processes can produce fine and uniform metal powders that exhibit excellent flowability and packing density, essential for powder metallurgy and additive manufacturing applications.

The automotive sector remains a significant consumer of metal powders, leveraging their properties to enhance the performance and efficiency of vehicles. With the growing focus on electric vehicles and lightweighting initiatives to improve fuel efficiency, the demand for metal powders in the automotive industry is expected to see continued growth. Similarly, the aerospace industry is increasingly utilizing metal powders for manufacturing components with high strength-to-weight ratios, critical for aircraft and spacecraft applications.

In the healthcare industry, metal powders are playing a crucial role in the production of medical implants, surgical instruments, and prosthetics. The biocompatibility and strength of metal powders make them ideal materials for manufacturing medical devices that require precision and reliability. As the global population ages and the demand for advanced healthcare solutions rises, the healthcare sector is likely to emerge as a key growth driver for the metal powder market.

In conclusion, the global metal powder market is witnessing a paradigm shift driven by industry demands for customized, high-performance materials, sustainable manufacturing practices, and technological innovations. Market players need to stay abreast of these trends, invest in research and development, and forge strategic partnerships to capitalize on the opportunities presented by the evolving landscape of metal powder applications across industries.**Segments**

Global Metal Powder Market, By Metal Form (Scrap/Recycled Metal, Ores), Production Method (Physical, Chemical, Mechanical), Compaction Technique (Cold Compaction, Hot Compaction), Type (Ferrous Metal Powder, Non-Ferrous Metal Powder), Application (Transportation and logistics, Industrial, Construction, Electrical and electronics Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of the Middle East and Africa) Industry Trends and Forecast to 2029.

The global metal powder market is a diverse landscape characterized by various segments that cater to the needs of different industries and applications. Metal forms such as scrap/recycled metal and ores offer distinct advantages and are utilized based on specific requirements. The production methods including physical, chemical, and mechanical play a crucial role in determining the quality and characteristics of metal powders. Compaction techniques such as cold compaction and hot compaction further influence the final properties of the metal powder products. The differentiation between ferrous and non-ferrous metal powders enables manufacturers to target specific market segments effectively. Applications ranging from transportation and logistics to industrial, construction, electrical and electronics showcase the versatility of metal powders in diverse sectors. Geographically, the market spans across regions like North America, Europe, Asia-Pacific, and the Middle East & Africa, each presenting unique growth opportunities and market dynamics for metal powder players.

**Market Players**

- ATI

- American Axle & Manufacturing, Inc.

- American Chemet Corporation

- AMETEK.Inc.

- Burgess-Norton

- CRS Holdings, LLC

- DAIDO STEEL

- Diamet Corporation

- DOWA HOLDINGS CO., LTD.

- ERASTEEL

- F. W. Winter Inc, & Co.

- Federal-Mogul Goetze (India) Limited

- fine-sinter Co., Ltd.

- GKN Sinter Metals Engineering GmbH

- Hoeganaes Corp.

- H.C. Starck Tungsten GmbH

- Showa Denko Materials Co., Ltd.

- Höganäs AB

- JFE Steel Corporation

- Kennametal, Inc.

- KOBE STEEL, LTD.

- Kymera International

- Miba AG

- Norilsk Nickel

- PMG Holding

- Rio Tinto Metal Powders

The global metal powder market is poised for sustained growth and evolution driven by a combination of factors encompassing market segmentation, technological advancements, and industry dynamics. The metal powder industry is witnessing a surge in demand due to its versatility and application across various sectors. From the automotive and aerospace industries to healthcare and electronics, metal powders play a crucial role in enhancing product performance, efficiency, and innovation. The differentiation between ferrous and non-ferrous metal powders allows manufacturers to cater to diverse market needs effectively. Moreover, advancements in production methods and compaction techniques enable the customization and optimization of metal powders for specific applications and end-use industries.

The market players in the metal powder industry are engaged in continuous research and development efforts to stay ahead of the curve and meet the evolving demands of customers across different sectors. Collaborations, mergers, and acquisitions are prominent strategies adopted by key players to enhance their market presence and expand their product portfolios. As the global industrial landscape evolves, propelled by technological advancements and changing consumer preferences, market players need to stay agile and responsive to emerging trends and market opportunities in the metal powder sector. The forecasted trends suggest a positive growth trajectory for the global metal powder market, with heightened focus on sustainability, innovation, and efficiency shaping the future of the industry.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Metal Powder Market : https://www.databridgemarketresearch.com/reports/global-metal-powder-market/companies

Key Questions Answered by the Global Metal Powder Market Report:

- What is the current state of the Metal Powder Market, and how has it evolved?

- What are the key drivers behind the growth of the Metal Powder Market?

- What challenges and barriers do businesses in the Metal Powder Market face?

- How are technological innovations impacting the Metal Powder Market?

- What emerging trends and opportunities should businesses be aware of in the Metal Powder Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-aerial-photogrammetry-software-market

https://www.databridgemarketresearch.com/reports/global-patient-recliner-market

https://www.databridgemarketresearch.com/reports/global-orthodontic-retainers-market

https://www.databridgemarketresearch.com/reports/global-pathological-examination-market

https://www.databridgemarketresearch.com/reports/global-power-plant-boiler-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 1011

Comments

0 comment