views

Welding technology has evolved significantly over the years, with advancements that improve efficiency, precision, and durability. Among these innovations, the laser beam welding tool has gained popularity due to its ability to deliver high-quality welds with minimal distortion. This cutting-edge technology is widely used in industries such as automotive, aerospace, electronics, and medical device manufacturing. In this article, we will explore the working principles, advantages, applications, and considerations of using a laser beam welding tool.

What is a Laser Beam Welding Tool?

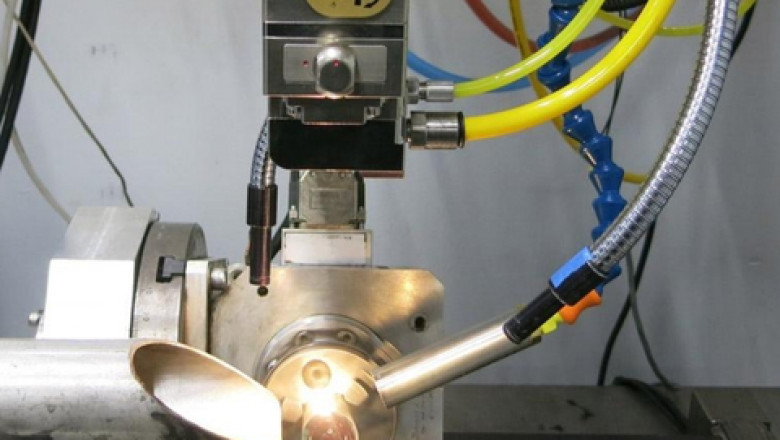

A laser beam welding tool (LBW) is a welding device that utilizes a concentrated laser beam to melt and fuse materials. This tool operates by generating a high-energy laser that creates a narrow and deep weld seam, making it ideal for applications requiring precision and strength. The laser beam can be controlled with extreme accuracy, ensuring clean and strong welds even on delicate or thin materials.

There are different types of laser beam welding systems, including:

- Continuous Wave Lasers: Used for deep penetration welding.

- Pulsed Lasers: Ideal for thin materials and delicate components.

- Fiber Lasers: Known for their high efficiency and low maintenance requirements.

- CO2 Lasers: Commonly used in industrial applications for thick materials.

Advantages of Laser Beam Welding Tools

The laser beam welding tool offers several benefits over traditional welding methods, making it a preferred choice in various industries. Some of the key advantages include:

1. High Precision and Accuracy

Laser welding provides pinpoint accuracy, making it ideal for intricate and delicate workpieces. This is particularly beneficial for industries requiring micro-welding, such as electronics and medical device manufacturing.

2. Minimal Heat Distortion

Unlike conventional welding methods that generate excessive heat, laser welding focuses the energy on a specific area, reducing thermal distortion and ensuring better structural integrity.

3. Faster Welding Speed

Laser welding is significantly faster than traditional welding methods, leading to increased productivity and cost savings for manufacturers.

4. Strong and Durable Welds

The deep penetration of the laser beam creates strong and reliable welds, even in high-stress applications such as aerospace and automotive components.

5. Ability to Weld a Variety of Materials

Laser beam welding tools can work with a wide range of metals, including stainless steel, aluminum, titanium, and even some non-metallic materials.

Applications of Laser Beam Welding Tools

The versatility of laser beam welding tools makes them valuable across multiple industries. Some of the most common applications include:

1. Automotive Industry

Laser welding is widely used in car manufacturing for assembling body panels, engine components, and exhaust systems due to its ability to produce strong and lightweight welds.

2. Aerospace Industry

In aerospace engineering, precision and durability are critical. Laser welding is used for assembling aircraft components, fuel tanks, and turbine blades.

3. Medical Device Manufacturing

Laser welding plays a crucial role in the production of medical instruments, implants, and surgical tools where precision and cleanliness are essential.

4. Electronics and Microfabrication

Micro-welding capabilities make laser welding ideal for electronic components such as circuit boards, battery connections, and sensors.

5. Jewelry and Watchmaking

The precision of laser welding is highly beneficial in the jewelry and watchmaking industries, where intricate and delicate work is required.

Considerations When Using a Laser Beam Welding Tool

Despite its many advantages, there are some factors to consider before adopting laser beam welding tools in industrial applications:

- Initial Cost: Laser welding systems can be expensive, but the investment is often justified by their efficiency and precision.

- Skill Requirement: Operators need specialized training to handle laser welding tools effectively.

- Material Compatibility: While laser welding works with many materials, some may require additional processing for optimal results.

Conclusion

The laser beam welding tool is a game-changer in modern manufacturing, offering unmatched precision, speed, and efficiency. With applications across industries such as automotive, aerospace, and medical device manufacturing, this technology is transforming the way materials are welded. While the initial investment may be high, the benefits in terms of productivity, durability, and accuracy make it a worthwhile choice for businesses seeking advanced welding solutions.

If you are looking for a high-quality laser beam welding tool, consider exploring the latest models that suit your specific industry needs and production requirements. 🚀

Comments

0 comment