views

"Electrically Conductive Epoxy Adhesive Market Size And Forecast by 2031

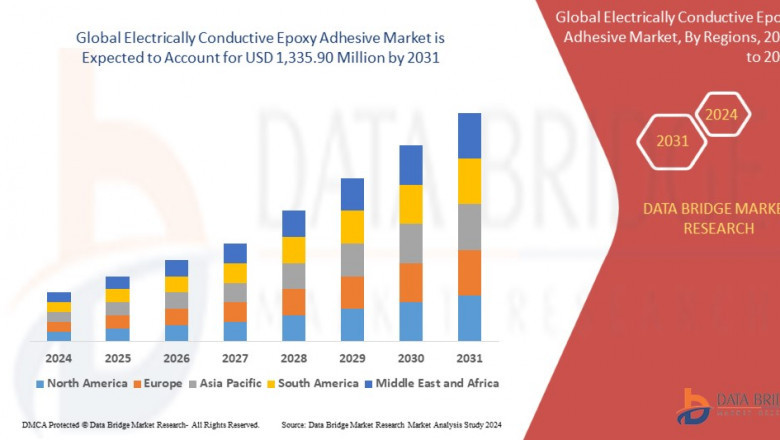

According to Data Bridge Market Research Data Bridge Market Research analyses that the Global Electrically Conductive Epoxy Adhesive Market which was USD 774.4 Million in 2023 is expected to reach USD 1335.9 Million by 2031 and is expected to undergo a CAGR of 7.10% during the forecast period of 2023 to 2031.

Our comprehensive Electrically Conductive Epoxy Adhesive Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-electrically-conductive-epoxy-adhesive-market

**Segments**

- Type:

- Silver Filled

- Copper Filled

- Carbon Nanotube Filled

- Others

- Application:

- Automotive

- Consumer Electronics

- Aerospace

- Medical Devices

- Others

- End-Use:

- Conductive Adhesive

- Sintering Additive

- Others

**Market Players**

- Henkel AG & Co. KGaA

- 3M

- H.B. Fuller Company

- Aremco

- Panacol-Elosol GmbH

- Master Bond

- AI Technology

- Parker Chomerics

- MG Chemicals

- Permabond Engineering Adhesives Ltd

- Panacol-Elosol GmbH

The electrically conductive epoxy adhesive market is expected to witness significant growth in the coming years. The market is segmented based on type, application, and end-use. In terms of type, the market includes silver-filled, copper-filled, carbon nanotube-filled, and others. The silver-filled segment is anticipated to dominate the market due to its high conductivity and widespread use in electronics applications. The copper-filled segment is also expected to grow steadily, driven by its cost-effectiveness and good electrical properties. Carbon nanotube-filled epoxy adhesives are gaining popularity for their excellent mechanical strength and conductivity.

Regarding applications, the market caters to industries such as automotive, consumer electronics, aerospace, medical devices, and others. The consumer electronics segment is projected to be a major consumer of electrically conductive epoxy adhesives due to the increasing demand for compact and lightweight electronic devices. The automotive sector is also a significant end-user, using these adhesives for various applications such as bonding electronic components and sensors. Aerospace and medical device industries are expected to offer lucrative opportunities for market growth as well.

In terms of end-use, the market encompasses conductive adhesive and sintering additive applications. Electrically conductive epoxy adhesives are widely used as conductive adhesives in electronics manufacturing for bonding components and providing electrical conductivity. The sintering additive segment is gaining traction in industries like aerospace and automotive for applications requiring high thermal and electrical conductivity.

Key market players active in the electrically conductive epoxy adhesive industry include Henkel AG & Co. KGaA, 3M, H.B. Fuller Company, Aremco, Panacol-Elosol GmbH, Master Bond, AI Technology, Parker Chomerics, MG Chemicals, Permabond Engineering Adhesives Ltd, and others. These companies are focusing on product innovations, strategic partnerships, and market expansion to strengthen their foothold in the competitive market landscape.

https://www.databridgemarketresearch.com/reports/global-electrically-conductive-epoxy-adhesive-market The global electrically conductive epoxy adhesive market is poised for robust growth in the foreseeable future, driven by various factors such as technological advancements, increasing demand for electronic devices, and expanding applications across industries. One key trend shaping the market is the growing emphasis on eco-friendly and sustainable adhesive solutions. Market players are increasingly investing in research and development to introduce bio-based electrically conductive epoxy adhesives that offer high performance while reducing environmental impact.

Another significant factor influencing market dynamics is the rising adoption of electric vehicles (EVs) and renewable energy systems. Electrically conductive epoxy adhesives play a crucial role in the manufacturing of EV components, such as battery packs, electronic control units, and powertrain systems. With the push towards decarbonization and clean energy initiatives, the demand for these adhesives in the automotive sector is expected to witness substantial growth.

Furthermore, the aerospace industry presents a lucrative opportunity for electrically conductive epoxy adhesive manufacturers. The need for lightweight materials with excellent conductivity properties in aircraft manufacturing has fueled the demand for advanced adhesive solutions. Electrically conductive epoxy adhesives are used in aerospace applications for bonding composite materials, electromagnetic interference shielding, and enhancing structural integrity.

Moreover, the healthcare sector is emerging as a promising end-user of electrically conductive epoxy adhesives, particularly in the production of medical devices and equipment. These adhesives are used in the assembly of electronics in medical devices, wearable sensors, and diagnostic tools, ensuring reliable electrical connections and performance. As the healthcare industry continues to innovate with digital health solutions and smart medical devices, the demand for electrically conductive adhesives is anticipated to rise.

In terms of market competition, key players are focusing on expanding their product portfolios to cater to diverse industry requirements. Customization of electrically conductive epoxy adhesive formulations to meet specific conductivity, thermal resistance, and adhesion properties is becoming essential to gain a competitive edge. Additionally, strategic collaborations and partnerships with raw material suppliers, technology providers, and end-users are crucial for market players to enhance their market presence and address evolving customer needs effectively.

Overall, the global electrically conductive epoxy adhesive market is poised for significant growth opportunities, propelled by technological advancements, expanding end-user industries, and increasing awareness regarding the benefits of these adhesive solutions. As manufacturers continue to innovate and align with sustainability trends, the market is expected to witness continued evolution and adoption across a wide range of applications.**Segments**

Global Electrically Conductive Epoxy Adhesive Market, Type (Isotropic Conductive Epoxy Adhesives, Anisotropic Conductive Epoxy Adhesives), Application (Automotive, Consumer Electronics, Aerospace, Biosciences, Others), Filler Material (Silver Fillers, Carbon Fillers, Copper Fillers, Others) – Industry Trends and Forecast to 2031.

The global electrically conductive epoxy adhesive market is witnessing significant growth, driven by advancements in technology and the increasing demand for electronic devices across various industries. The market is segmented based on different parameters, including type, application, and filler material. Isotropic and anisotropic conductive epoxy adhesives cater to specific requirements in different applications, providing versatility and performance. These adhesives find extensive use in automotive, consumer electronics, aerospace, biosciences, and other sectors, offering a wide range of applications for electrical conductivity. Silver, carbon, copper, and other filler materials provide unique properties to the adhesives, making them suitable for diverse end-use applications.

**Market Players**

- Master Bond Inc. (U.S.)

- Panacol-Elosol GmbH (Germany)

- Aremco Products Inc. (U.S.)

- DuPont (U.S.)

- SOLVAY (Belgium)

- Dow (U.S.)

- Henkel AG & Co. KgaA (Germany)

- 3M (U.S.)

- Bostik (France)

- Sika AG (Switzerland)

- H.B. Fuller (U.S.)

- BASF SE (Germany)

- DAP Global Inc. (U.S.)

- Owens Corning (U.S.)

- The Chemours Company (U.S.)

- Paroc Group (Finland)

- Kingspan Group (Ireland)

- Knauf Insulation (U.S.)

- DAIKIN (Japan)

- GAF (U.S.)

- SOLVAY (Belgium)

- Saint-Gobain (France)

- Franklin International (U.S.)

- Illinois Tool Works Inc. (U.S.)

- AVERY DENNISON CORPORATION (U.S.)

Market players in the electrically conductive epoxy adhesive industry are continuously innovating to meet evolving market demands and stay competitive. With a focus on product development, strategic partnerships, and market expansion, these companies are enhancing their market presence and offering a diverse range of solutions to customers.

The increasing emphasis on eco-friendly and sustainable adhesive solutions is a notable trend shaping the market landscape. Companies are investing in research and development to introduce bio-based electrically conductive epoxy adhesives that offer high performance while reducing environmental impact. Customization of adhesive formulations to meet specific industry requirements is becoming essential for market players to gain a competitive edge and cater to a wide range of applications effectively.

The rising adoption of electric vehicles (EVs) and renewable energy systems is driving the demand for electrically conductive epoxy adhesives in automotive applications. These adhesives play a crucial role in the manufacturing of various EV components, supporting the industry's shift towards decarbonization and clean energy initiatives. The aerospace sector presents lucrative opportunities for market players, with advanced adhesive solutions being utilized for bonding composite materials and enhancing structural integrity in aircraft manufacturing.

In the healthcare industry, the use of electrically conductive epoxy adhesives in medical device assembly is gaining momentum, contributing to the sector's innovation in digital health solutions and smart medical devices. As the demand for compact and lightweight electronic devices continues to rise across industries, the market for electrically conductive epoxy adhesives is expected to witness sustained growth in the coming years.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Electrically Conductive Epoxy Adhesive Market : https://www.databridgemarketresearch.com/reports/global-electrically-conductive-epoxy-adhesive-market/companies

Key Questions Answered by the Global Electrically Conductive Epoxy Adhesive Market Report:

- What is the current state of the Electrically Conductive Epoxy Adhesive Market, and how has it evolved?

- What are the key drivers behind the growth of the Electrically Conductive Epoxy Adhesive Market?

- What challenges and barriers do businesses in the Electrically Conductive Epoxy Adhesive Market face?

- How are technological innovations impacting the Electrically Conductive Epoxy Adhesive Market?

- What emerging trends and opportunities should businesses be aware of in the Electrically Conductive Epoxy Adhesive Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-pretreatment-coatings-market

https://www.databridgemarketresearch.com/reports/global-glycomics-market

https://www.databridgemarketresearch.com/reports/global-wide-bandgap-wbg-power-semiconductor-devices-market

https://www.databridgemarketresearch.com/reports/global-hemoglobin-testing-market

https://www.databridgemarketresearch.com/reports/global-polymeric-modifiers-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 982

Comments

0 comment