P-Shot Treatment in Dubai: A Revolutionary Solution for...

P-Shot Treatment in Dubai could be the perfect choice. With world-class cli...

-

P-Shot Treatment in Dubai could be the perfect choice. With world-class cli...

New to crypto and unsure where to start? Discover what makes a crypto excha...

Strong Vendor Network: An experienced designer has reliable connections wit...

Problem-Solving Skills: From sudden weather changes to sand-sensitive décor...

Learn how AI trading bots use advanced algorithms to analyze crypto markets...

Explore how a Wazirx clone script can help you build a powerful and secure...

If your bathroom is looking a little tired, outdated, or no longer fits you...

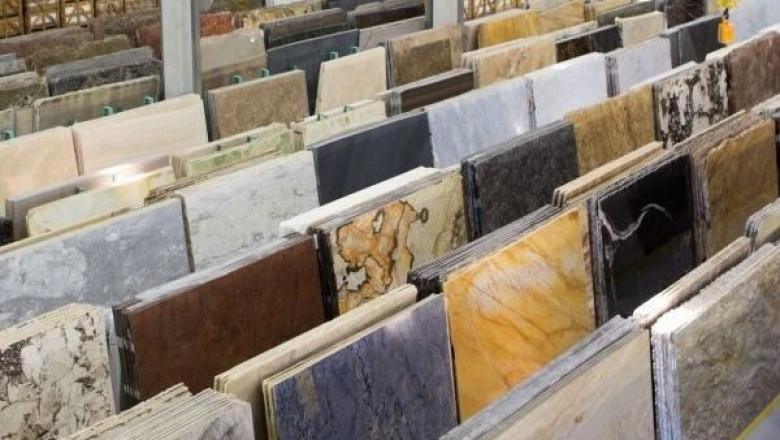

SSKG (Sri Sai Kripa Stones) is a trusted Jaipur-based supplier of premium t...